•FQL450S is fully automatic L bar sealer which is widely used in mass production packaging line with high efficiency.

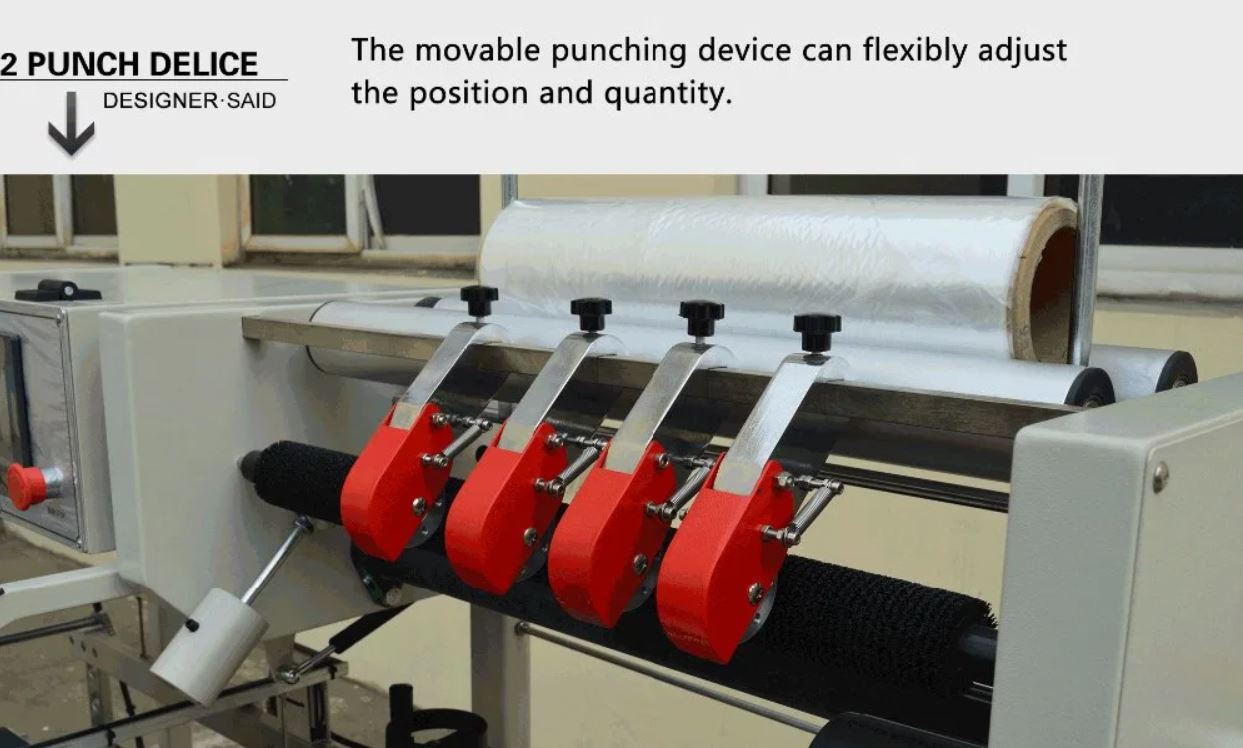

•With movable type punching device, you can switch the punching position and control the pinholes number.

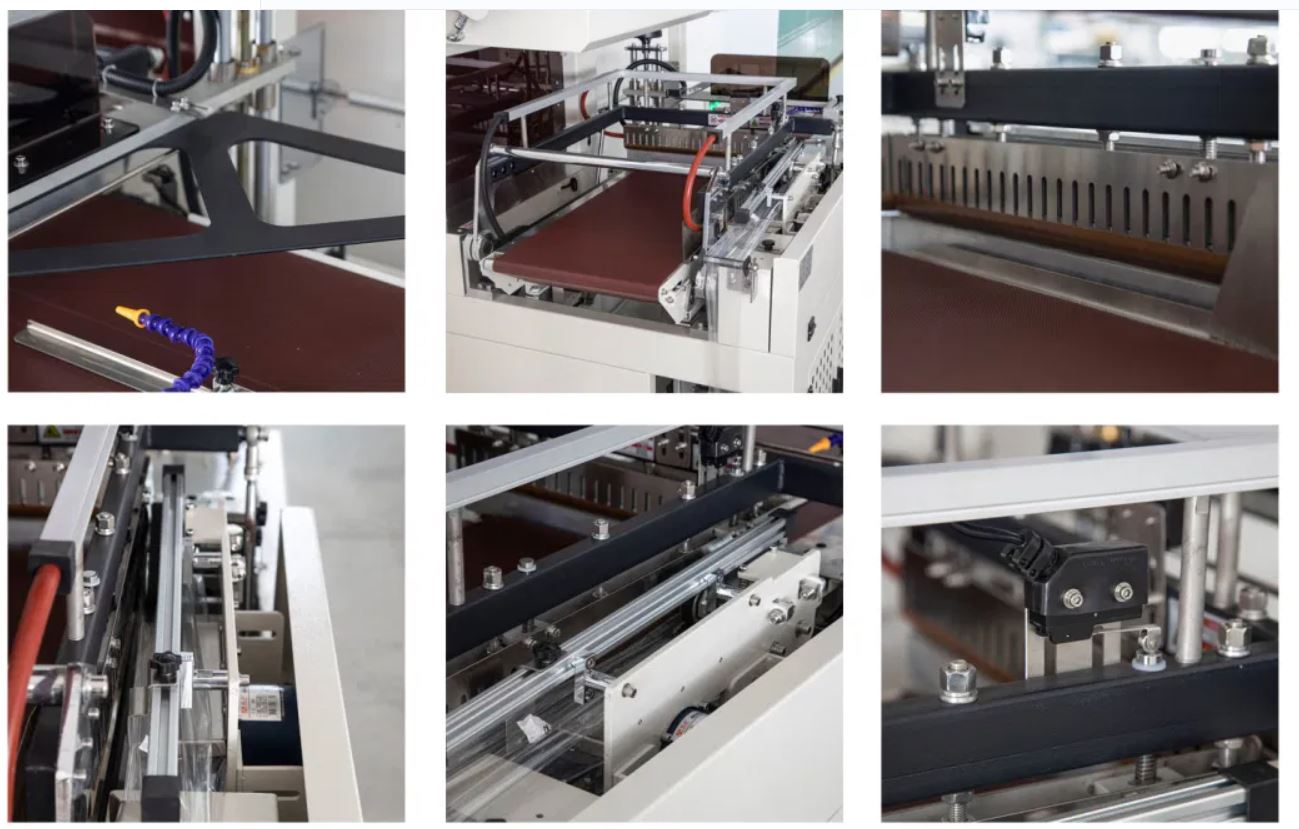

•Sealing knife uses the special steel knife with Daikin Teflon which is anti-stick coating & anti-high temperature. So the sealing will not have cracking, coking and smoking with zero pollution.

•Using digital temperature controller which built-in PID function. Sealing blade temperature is extremely sensitive and accurate which can be set arbitrarily.

•Imported photoelectric sensor, positioning accuracy, fast response.

•Adopt Panasonic PLC programmable controller and WEINVIEW 7-inch man machine interface, simple operation.

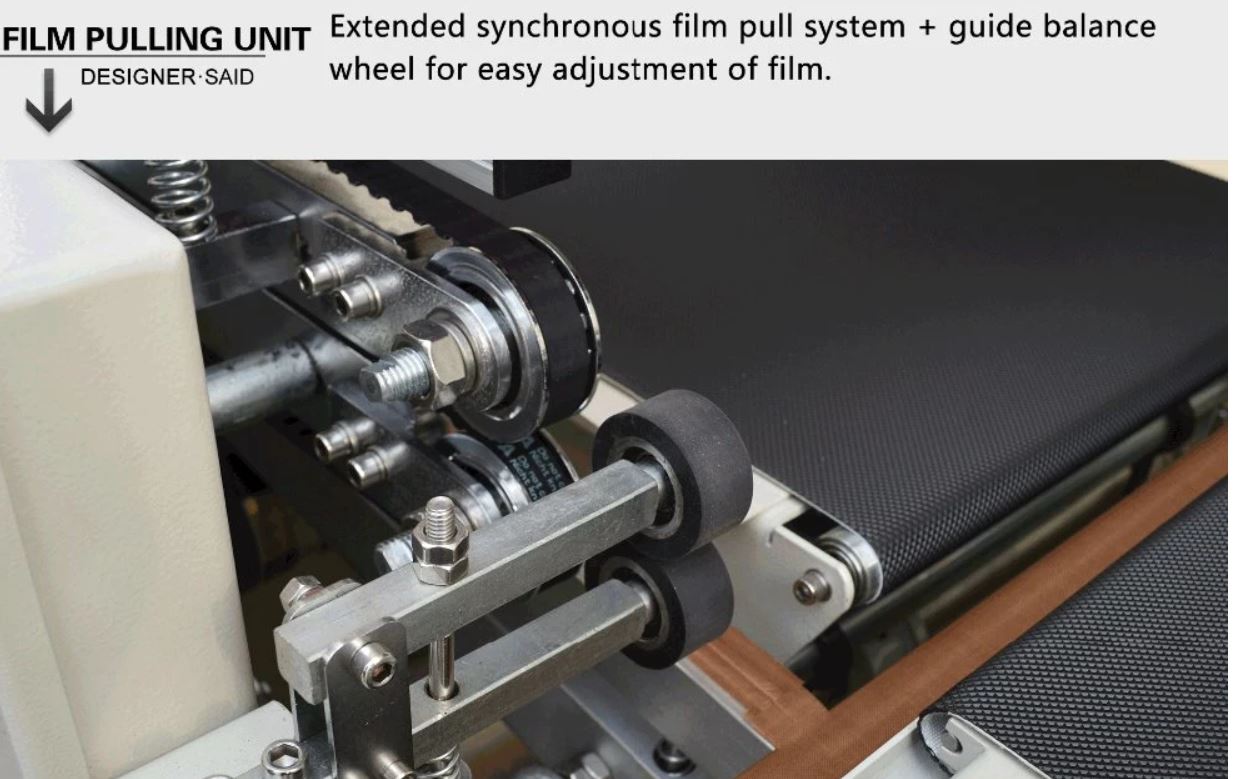

• Manual adjustment film-guide system and feeding conveyor platform make the machine suitable for different width and height items.

•Equipped with automatic scrap recycling mechanism, built-in film broken alarm function.

•The sealing blade itself is also quipped with automatic protection function which effectively prevent from accidental cutting.

•Automatic mode and manual mode can be switched at any time which convenient to replace the shrink film.

•The entire machine realizes unmanned operation with the production line connecting.

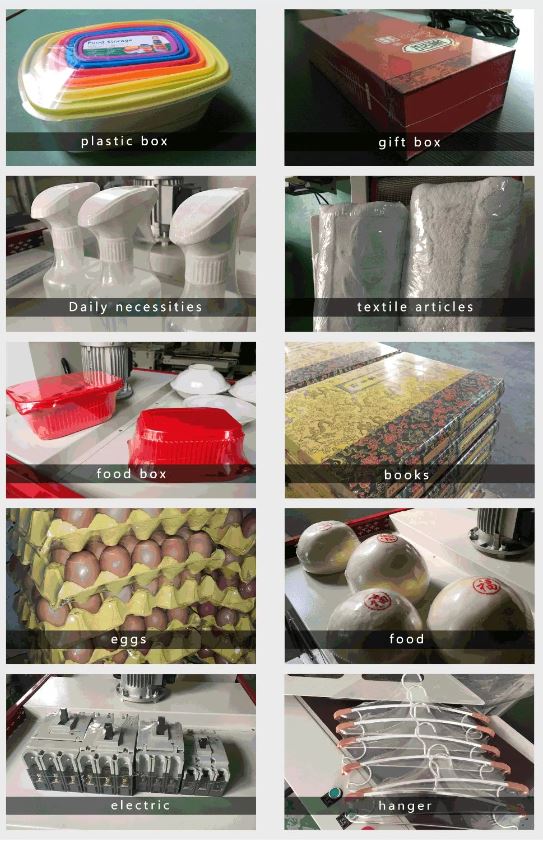

•Apply to daily necessities, food, cosmetics, pharmaceutical, hardware and other industries shrinking packaging.

•BS4522N shrink tunnel adopts the design of internal double recycling air fan, so that the hot air in the tunnel is even, constant temperature.

•The machine uses stainless steel finned heating tube which has a long service life and high heating efficiency.

•Chain bar conveying , using hollow steel covered with durable imported silicone tube, each bar can rotate freely.

•Suitable for POF, PVC, PP, PET heat shrinkable film

|

Model

|

FQL-450S

|

|

Power supply

|

220V 1/3ph 50/60Hz

|

|

Power

|

1.8KW

|

|

Packing Size

|

(L+H)<550mm (W+H)<400mm (H)<130mm

|

|

Sealing Size

|

(L)550×(W)450mm

|

|

Table height

|

800mm

|

|

Packaging speed

|

15~30pcs/min(Determined by product size)

|

|

Air source

|

6kg/cm2

|

|

Shrink film

|

POF fold film

|

|

Shrink film size

|

(W)≤530mm;(D)≤250mm;(weight)≤35KG

|

|

Sealing form

|

L type full closed

|

|

Overall dimension

|

(L)1800×(W)800×(H)1480mm

|

|

Package size

|

(L)1850×(W)900×(H)1630mm

|

|

G./N. weight

|

390/320KG

|

|

Model

|

BS4522N

|

|

Power supply

|

380V 3ph 50/60 Hz

|

|

Power

|

12KW

|

|

Table height

|

780+50mm

|

|

Conveyor load

|

30KG

|

|

Conveyor speed

|

1-15m/min

|

|

Tunnel size(L×W×H)

|

1500×450×220mm

|

|

Overall dimension(L×W×H)

|

1910×700×1320mm

|

|

Package size(L×W×H)

|

1960×800×1470mm

|

|

G./N. weight

|

250/200Kg

|

Reviews

There are no reviews yet.